Power rails and nurseries FRP / GRP

The FRP / GRP Electric Power Guns The Pedram Engineering Group is packed with traditional conventional products that encounter serious corrosion problems. (Seafront, chemical, wetlands and areas with high temperature fluctuations) are highly recommended.

These types of power beams are long life-free, which can be used in different areas without the need to hold the beams.

The use of FRP / GRP composite electric arrays is very economical due to its lightness, the installation of awn, without the need to maintain surfaces, coloring and digging the ground.

Benefits and features of the beamFRP

- Resistant to chemicals and chemicals

- Lighter than steel, concrete, wood, thus reducing the cost of transmission and execution

- High mechanical strength

- Better the beauty

- The rigidity and toughness that cause the least deformation to the steel and concrete beams.

- Electrical exponent

- Low installation cost

- No maintenance

Usage

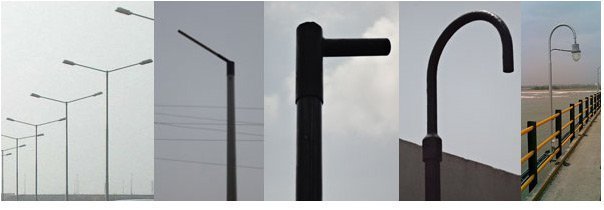

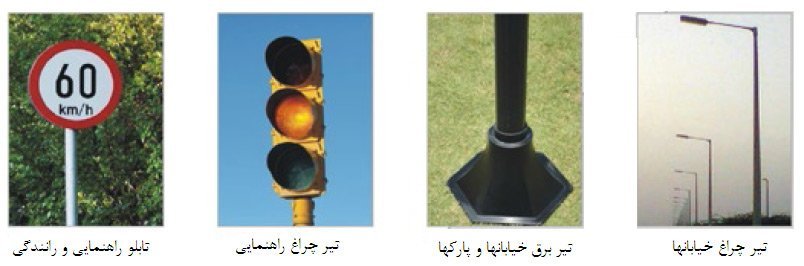

- Beams of the street

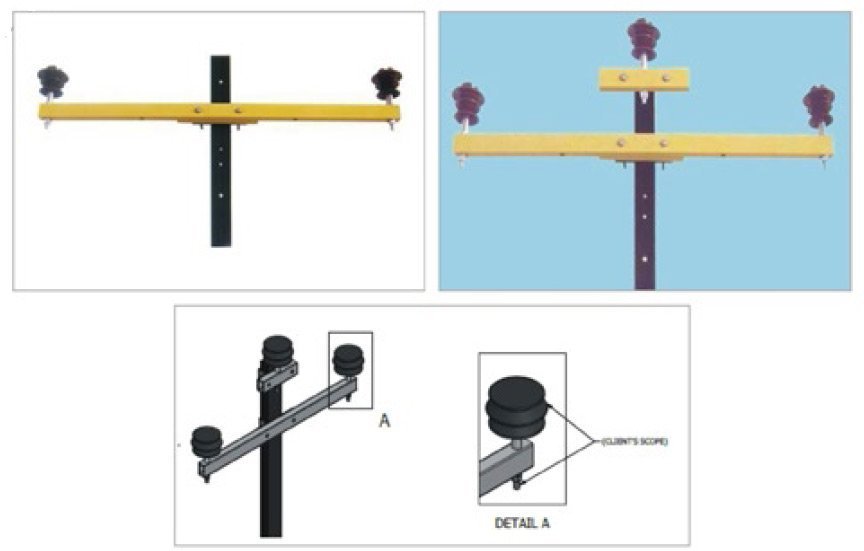

- Traffic light

- Traffic signs for traffic signs

- Light beams in chemical plants

- Light beams in parks, parking lots, places and so on ...... .

- advertisement boards

- Flagstones

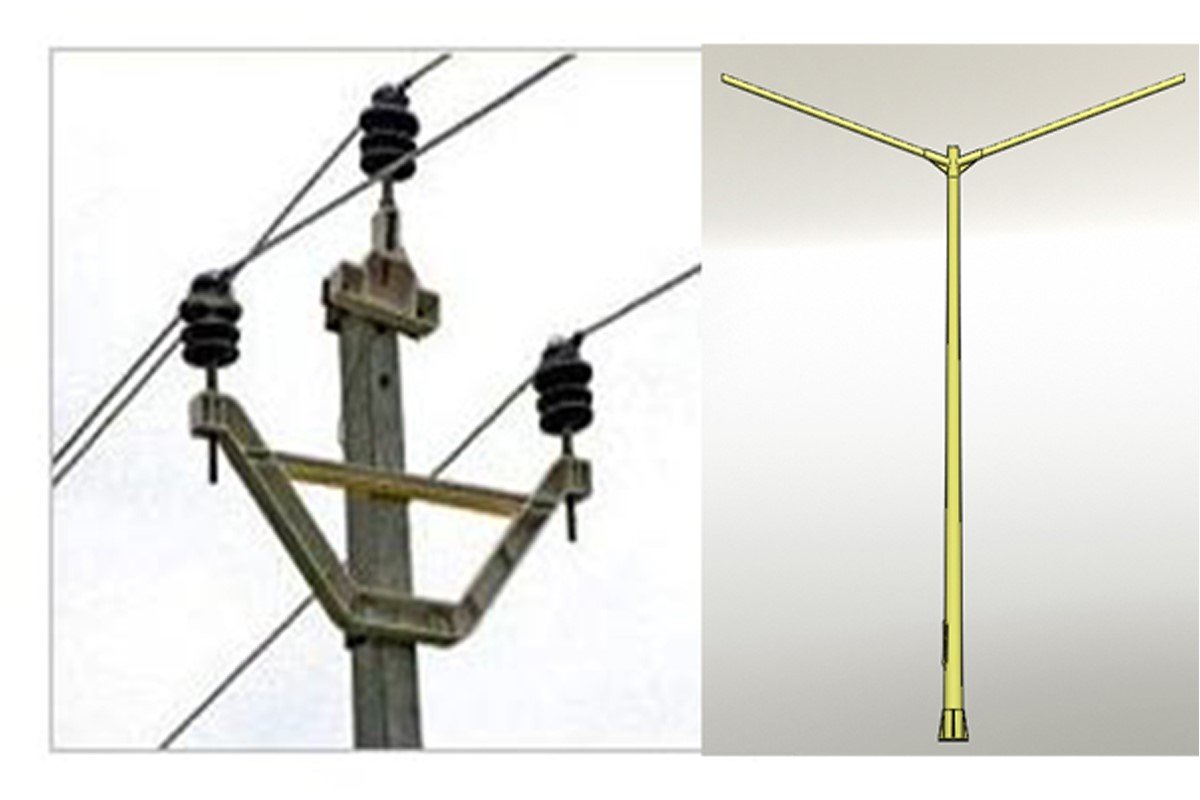

- The beams and towers for the transmission of telephone and electric lines and many other uses

Comparison of FRP / GRP composite arc welding with traditional materials

| Metal beams | FRP / GRP beams | Property |

|---|---|---|

| High corrosion | Anti-corrosion | Corrosion |

| Enough | Excellent | Beauty |

| needs | No need | Need for dirt |

| medium | Very long | life span |

| Need for high maintenance | Without maintenance | maintenance |

| Very heavy | Very light | Weight |

| External Covering | Color resistant and UV resistant | Color |

| Repeated coloring is required | Not necessary | coloring |

| Hard | Easy | Movement |

| Concrete foundation is mandatory | The foundation is optional | Installation |

| too much | very little | Transfer cost |

| too much | very little | Installation costs |

| A few | Single | Structure |

| Conductor | Insulated and non-conductive, anti-shock | Conducting electricity |

Technical specifications

| Details | Units | Test Methods |

|---|---|---|

| Content Glass | 45-55 % | ASTM D 2584 |

| Water absorption | < 0.5 % | ASTM D 570 |

| Tensile strength | 200 ± 50 Mpa | ASTM D 638 |

| Torsional strength | 250 ± 50 Mpa | ASTM D 790 |

| Compressive strength | 200 ± 50 Mpa | ASTM D 695 |

| Performance strength | 250 ± 50 Mpa | ASTM D 638 |

| Elasticity Of Modular | 1500 Mpa/ 2500 Mpa | ASTM D 638 |

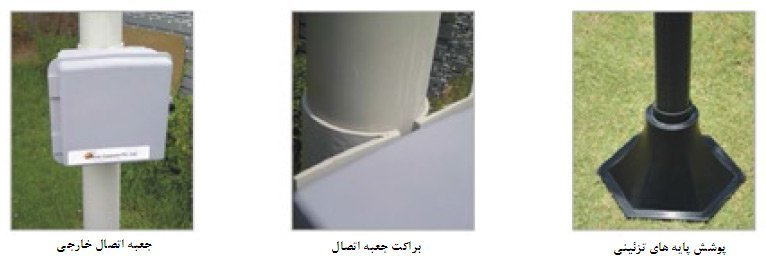

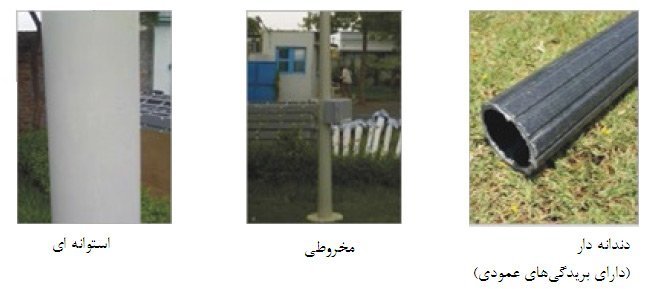

Installation type

Accessories