Grating Composite FRP / GRP Molding

FRP composite gratings suitable for use in floors, locks, decks in industrial environments with high corrosion resistance and excellent load bearing capacity. Other UV-reinforced fiber additives These types of products with resin systems Due to the inhibitors of this type of high-strength gratifications, excellent corrosion resistance and safety and long lifetimes are known in the hard industrial environments.

Molding gratings are manufactured in accordance with the highest international standards by choosing a resin system and designing materials and structures according to the terms of use for long-term use in the intended use to replace traditional traditional products that have a lower installation, implementation, maintenance and maintenance cost. , Have a longer life span than steel and galvanized steel.

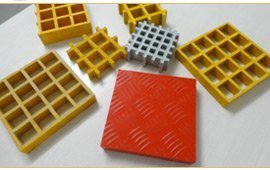

Molding gratings are available in a polyester resin, vinyl ester or phenolic resin that has all of its self-extinguishing and UV-resistant properties.

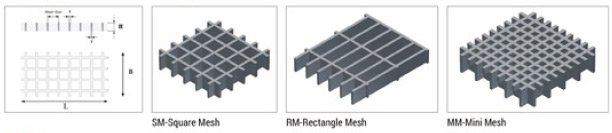

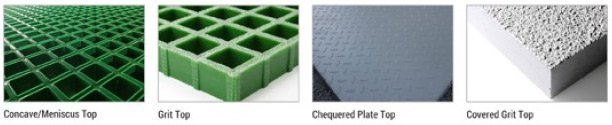

Molded composite gratings are in mesh structures and different levels for desired applications.

Compare with traditional products

| Parameters | Composite Grating | HOT DIPPED GI | SS |

|---|---|---|---|

| Life Span | High | Moderate | High |

| Strength to Weight Ratio | High | Low | Low |

| Life Cycle cost | Low | High | High |

| Corrosion Resistivity | Very High | Moderate | High |

| Chemical Resistivity | Very High | Moderate | High |

| Electrical Conductivity | Nil | High | High |

| EMI/RFI Transparency | High | Nil | Nil |

| Installation Cost | Low | Moderate | Moderate |

| Handing | Very Easy | Difficult | Difficult |

| Anti Skid | Available | NA | NA |

| Colour Range | Available | NA | NA |

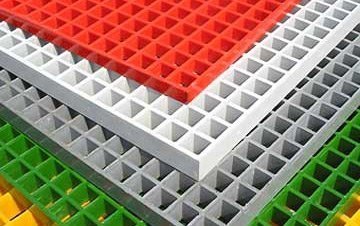

FRP / GRP Molding Composite Grating Structure

Molded composite gratings are made with hot molds and hot cooking.

The reinforcement consists of glass fibers in the specified layers, which distributes the uniform transport of loads in all directions in a longitudinal and transverse equally.

Generating fiberglass gratings are made regularly with specified resin systems. Standard, except for glass, approximately 35% of the green, yellow and other colors are capable of producing on the basis of the rails.

Resin systemIn the first step, with the right choice of rendering system, the solution and reliability are obtained for long-term use with the highest qualities in the desired applications.Pedram Engineering Group's composite gratings are available in five standard resin standards that are highly affordable while maintaining the highest standards.

Resin system used in FRP / GRP composite grating

| Resin Type | Resin Base | Description | Flame Spread rating ASTM E-84 |

|---|---|---|---|

| Type V | Vinyl Ester | Superior Corrosion Resistance & Fire Retardant | Class 1.25 or less |

| Type IFR | Isopthalic Polyester | Industrail Grade corrosion Resistant & Fine retardant | Non fire retardant |

| Type I | Isopthalic Polyester | Industrail Grade corrosion Resistant in acidic environment | Class 1.25 or less |

| Type P | Phenolic | Low smoke and superior fire resistance | Class 1. 5 or less |