FRP / GRP composite polythene gratings

Pallet welded gratings are known for their high strength, corrosion resistance, life span and safety in hard industrial environments and are manufactured in accordance with the highest international standards.

Designing Pedram's engineering team enables interconnected profiles to be used for many years to come and replace traditional traditional products.

Lightweight, easy to install, effective in costing a better choice to replace steel and galvanizing in the main industries.

Variation in Paltrogen Products Pedram Engineering Group meets the needs of high load bearing and safety of these products.

Load bearing

Unlike mudging gratings, the strength is evenly distributed in both longitudinal and transverse directions. Pallet-iron gratings are much more powerful in the longitudinal direction of the load of interconnected bars and mounted grooves.

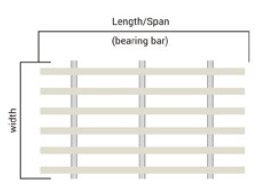

The size of composite gratings in width (dimensions of the T shaped bars) is determined by the length or extent of the load (bearing dimensions).

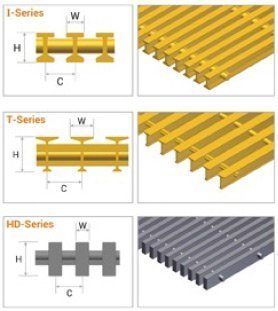

The load bearing used in industrial gratings is Paldrudd I turbine and section T, which are 25 mm and 38 mm deep.

For example, the grinding depth of 25 mm is mounted horizontally in the direction of the T-shaped rod, while for a depth of 38 mm and 50 mm for the T-bar, it is installed vertically.

| - | H-Height (mm) | W-Top width (mm) | C-Spacing (mm) | Open Area (%) |

|---|---|---|---|---|

| I-1040 | 25 | 15 | 25 | 40 |

| I-1050 | 25 | 15 | 30 | 50 |

| I-1060 | 25 | 15 | 38 | 60 |

| I-1540 | 38 | 15 | 25 | 40 |

| I-1550 | 38 | 15 | 30 | 50 |

| I-1560 | 38 | 15 | 38 | 60 |

| T-1033 | 25 | 25 | 38 | 33 |

| T-1050 | 25 | 25 | 50.8 | 50 |

| T-1517 | 38 | 25 | 30.5 | 17 |

| T-1533 | 38 | 25 | 38 | 33 |

| T-1550 | 38 | 25 | 50.8 | 50 |

| HD-1540 | 38 | 15 | 25 | 40 |

| HD-1550 | 38 | 15 | 30 | 50 |

| HD-1560 | 38 | 15 | 38 | 60 |

Contact the Corrosion and Composite Corrosion Experts to determine the dimensions, size and standard of load bearing compliance.

Embed and Install

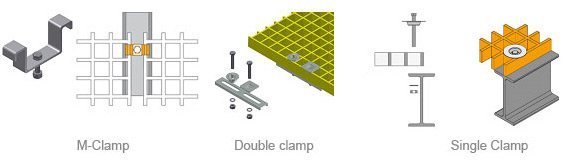

Accessories:

•Use of the L-Angle pallet jacket composite profile as a frame for mounting and tightening of FRP / GRP composite palletized gratings

Embed:

•Use of support and installation tools from Stanholes Steel Sets to install FRP / GRP composite gratings. Avoid moving and slipping. Use at least 4 ports for each panel..

Compare with traditional traditional products

| Parameters | Composite Grating | HOT DIPPED GI | SS |

|---|---|---|---|

| Life Span | High | Moderate | High |

| Strength to Weight Ratio | High | Low | Low |

| Life Cycle cost | Low | High | High |

| Corrosion Resistivity | Very High | Moderate | High |

| Chemical Resistivity | Very High | Moderate | High |

| Electrical Conductivity | Nil | High | High |

| EMI/RFI Transparency | High | Nil | Nil |

| Installation Cost | Low | Moderate | Moderate |

| Handing | Very Easy | Difficult | Difficult |

| Anti Skid | Available | NA | NA |

| Colour Range | Available | NA | NA |

Resin system

In the first step, with the right choice of rendering system, the solution and reliability are obtained for long-term use with the highest qualities in the desired applications.

Pedram Engineering Group's composite gratings are available in five standard resin standards that are highly affordable while maintaining the highest standards.

Resin system used in composite gratingFRP/GRP

| Resin Type | Resin Base | Description | Flame spread rating ASTM E84 |

|---|---|---|---|

| Type V | Vinyl Ester | Superior Corrosion Resistance & Fire Retardant | Class 1.25 or less |

| Type IFR | Isopthalic Polyester | Industrial Grade Corrosion resistance & fire retardant | Non fire retardant |

| Type I | Isopthalic Polyester | Industrial Grade Corrosion resistance in acidic environment | Class 1.25 or less |

| Type P | Phenolic | Low smoke and superior fire resistance | Class 1. 5 or less |